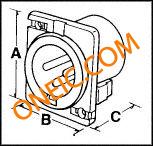

XLB-3-32

XLR male connectors for audio equipment with solder terminals

Manufacturer: itt

series introduction

# Introduction to the XLB - 3 - 32 Product Series

## Overview

The XLB - 3 - 32 product series represents a cutting - edge line of industrial equipment engineered to meet the diverse and demanding requirements of modern manufacturing, processing, and related industries. This series combines advanced technology, robust construction, and user - friendly features to deliver high - performance solutions for a wide range of applications.

## Key Features

### 1. High - Precision Performance

- **Accurate Control**: The XLB - 3 - 32 series is equipped with state - of the - art control systems that ensure precise operation. Whether it's controlling temperature, pressure, or speed, these systems can maintain tight tolerances, resulting in consistent and high - quality output. For example, in a manufacturing process where precise temperature control is crucial for product quality, the XLB - 3 - 32 can regulate the temperature within a very narrow range, minimizing product defects.

- **Advanced Sensors**: Integrated with high - sensitivity sensors, the series can accurately detect and measure various parameters. These sensors provide real - time data to the control system, enabling quick adjustments and ensuring optimal performance. For instance, pressure sensors can detect even the slightest changes in pressure, allowing the equipment to respond immediately to maintain a stable operating environment.

### 2. Robust Construction

- **Durable Materials**: The products in the XLB - 3 - 32 series are built using high - quality and durable materials. The frames and components are made from strong alloys and reinforced plastics that can withstand harsh industrial environments, including high temperatures, corrosive substances, and mechanical stress. This ensures a long service life and reduces the need for frequent replacements.

- **Rugged Design**: The overall design of the series is rugged and resistant to wear and tear. It is engineered to handle heavy - duty operations without compromising on performance. The equipment's structure is designed to distribute stress evenly, preventing premature failure and ensuring reliable operation over an extended period.

### 3. Energy Efficiency

- **Optimized Power Consumption**: The XLB - 3 - 32 series is designed with energy efficiency in mind. Advanced power management systems are incorporated to reduce energy consumption without sacrificing performance. For example, the equipment can automatically adjust its power usage based on the workload, ensuring that it only consumes the necessary amount of energy.

- **Energy - Saving Technologies**: The series may also feature energy - saving technologies such as variable frequency drives (VFDs). VFDs can adjust the speed of motors according to the actual demand, resulting in significant energy savings. This not only reduces operating costs but also contributes to a more sustainable environment.

### 4. User - Friendly Interface

- **Intuitive Controls**: The products are equipped with an intuitive control panel that is easy to operate. The interface features clear displays and simple controls, allowing operators to quickly set up and adjust the equipment. Even operators with limited technical knowledge can easily understand and use the controls, reducing the learning curve and improving productivity.

- **Remote Monitoring and Control**: Many models in the XLB - 3 - 32 series support remote monitoring and control capabilities. Through a dedicated software application or a web - based interface, operators can monitor the equipment's performance, adjust settings, and receive real - time alerts from anywhere. This feature is particularly useful for large - scale industrial facilities where multiple units need to be managed efficiently.

## Applications

### 1. Manufacturing Industry

- **Plastic Processing**: In the plastic injection molding process, the XLB - 3 - 32 series can be used to control the temperature and pressure of the injection molding machine. Its high - precision performance ensures that the plastic parts are molded with consistent quality, reducing waste and improving production efficiency.

- **Metal Fabrication**: For metal stamping and forming operations, the series can provide

Images for reference

Image Preview