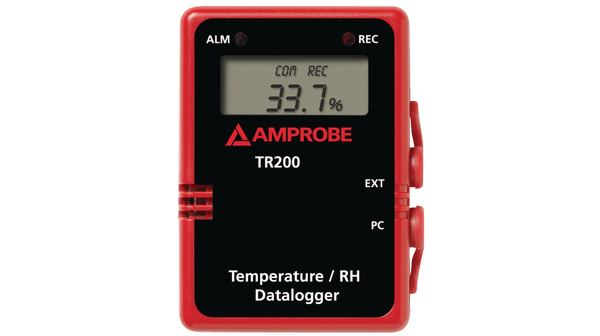

TR200

Environmental data loggers, fuses, and industrial transformers for diverse applications

Manufacturer: ['beha-amprobe', 'mersen', 'mornsun', 'aie', 'ferraz-shawmut', 'amphenol', 'stanley-electric', 'amprobe']

series introduction

# Unveiling the TR200 Product Series: A Technological Marvel for Precision and Performance

## Introduction

In the ever - evolving landscape of measurement and testing equipment, the TR200 product series stands out as a paragon of innovation, precision, and reliability. Engineered to meet the diverse needs of industries ranging from manufacturing and engineering to quality control and research, the TR200 series offers a comprehensive suite of solutions for surface roughness measurement.

## Design and Build

### Ergonomic Design

The TR200 series is designed with the user in mind. Its compact and lightweight form factor allows for easy handling, whether you are conducting on - site measurements in a factory floor or performing detailed laboratory analysis. The device fits comfortably in the hand, reducing fatigue during extended use. The well - placed buttons and controls ensure intuitive operation, enabling even novice users to quickly master the measurement process.

### Robust Construction

Built to withstand the rigors of industrial environments, the TR200 series features a durable housing that protects the internal components from dust, moisture, and mechanical shocks. The high - quality materials used in its construction guarantee long - term reliability, minimizing downtime and maintenance costs. This makes it an ideal choice for harsh working conditions where other instruments may fail.

## Technical Specifications

### Measurement Capabilities

The TR200 series offers a wide range of measurement parameters, including Ra (arithmetical mean deviation of the profile), Rz (average maximum height of the profile), Rq (root - mean - square deviation of the profile), and many others. With a high - precision probe, it can accurately measure surface roughness on various materials such as metals, plastics, ceramics, and composites. The measurement range is typically from 0.02μm to 10μm, providing sufficient resolution for most applications.

### High - Speed Sampling

Equipped with advanced sampling technology, the TR200 series can capture data at a high speed. This allows for rapid measurement of large surface areas, increasing productivity in industrial settings. The fast sampling rate also ensures that even small surface irregularities are accurately detected, providing a detailed and comprehensive analysis of the surface texture.

### Display and Data Storage

The device features a clear and easy - to - read LCD display that shows measurement results in real - time. It can also display graphical representations of the surface profile, allowing users to visually assess the surface quality. In addition, the TR200 series has built - in data storage capabilities, which can store a large number of measurement results. This data can be easily transferred to a computer via a USB interface for further analysis and reporting.

## Software and Connectivity

### User - Friendly Software

The TR200 series comes with dedicated software that provides advanced data analysis and reporting functions. The software allows users to customize measurement parameters, generate detailed reports, and compare measurement results over time. It also offers statistical analysis tools, such as histograms and trend analysis, which can help users identify patterns and trends in surface roughness data.

### Connectivity Options

In addition to the USB interface, the TR200 series may support other connectivity options, such as Bluetooth or Wi - Fi. This enables seamless integration with other devices and systems, such as mobile phones, tablets, and industrial networks. Users can remotely monitor and control the measurement process, share data with colleagues, and integrate the measurement results into existing quality management systems.

## Applications

### Manufacturing

In the manufacturing industry, the TR200 series is used to ensure the quality of machined parts. It can be used to measure the surface roughness of turning, milling, grinding, and other machining processes, helping manufacturers to optimize their production processes and meet strict quality standards.

### Automotive

In the automotive industry, the TR200 series is used to measure the surface roughness of engine components, transmission parts, and brake discs. This

Images for reference

Image Preview

Image Preview