SMD125

Surface mount resettable fuses for circuit protection

Manufacturer: ['raychem', 'littelfuse', 'tyco', 'sea-land', 'others']

series introduction

# Unveiling the SMD125 Product Series: Precision, Performance, and Innovation in Surface - Mount Technology

## Introduction

In the fast - paced world of electronics, where miniaturization, reliability, and high - performance are non - negotiable, the SMD125 product series emerges as a game - changer. This comprehensive range of surface - mount devices (SMDs) is engineered to meet the diverse and evolving needs of modern electronic applications, from consumer electronics to industrial control systems.

## Design and Form Factor

The SMD125 series is characterized by its compact and standardized surface - mount design. With a precisely engineered footprint, these components are optimized for automated pick - and - place manufacturing processes, enabling high - speed assembly on printed circuit boards (PCBs). The small size not only saves valuable board space but also allows for more complex and densely packed circuit designs. This is particularly crucial in today's electronics, where devices are becoming smaller and more feature - rich with each new generation.

The physical construction of the SMD125 components is built to withstand the rigors of the manufacturing process, including soldering at high temperatures. The robust packaging materials ensure that the internal components are well - protected from mechanical stress, moisture, and other environmental factors, contributing to the long - term reliability of the end - product.

## Electrical Performance

### High - Quality Components

At the heart of the SMD125 series are high - quality electrical components. Whether it's resistors, capacitors, or inductors, each part is designed to offer excellent electrical characteristics. For example, the resistors in the SMD125 series have low tolerance values, ensuring accurate and stable resistance over a wide range of operating conditions. This precision is essential in applications where even small variations in resistance can affect the performance of the entire circuit.

### Wide Operating Range

The SMD125 components are designed to operate over a wide range of temperatures, voltages, and frequencies. This makes them suitable for a variety of environments and applications. In industrial settings, where temperature fluctuations can be significant, the SMD125 series can maintain its performance without degradation. Similarly, in high - frequency applications such as wireless communication devices, the components can handle the demanding electrical signals with minimal loss.

### Low Power Consumption

In an era where energy efficiency is a top priority, the SMD125 series shines. The components are engineered to consume minimal power while delivering optimal performance. This not only reduces the overall power consumption of the electronic device but also helps in extending the battery life of portable devices.

## Applications

### Consumer Electronics

The SMD125 series finds extensive use in consumer electronics such as smartphones, tablets, and wearables. In smartphones, for example, the compact size of the SMD125 components allows for the integration of more features into a smaller form factor. The high - performance electrical characteristics ensure smooth operation of the device, from the touchscreen interface to the wireless communication modules.

### Automotive Electronics

In the automotive industry, reliability and performance are of utmost importance. The SMD125 series meets these requirements, making it suitable for use in automotive electronics systems such as engine control units (ECUs), infotainment systems, and safety sensors. The components can withstand the harsh automotive environment, including high vibrations, temperature variations, and electrical interference.

### Industrial Automation

Industrial automation systems rely on precise and reliable electronic components. The SMD125 series is well - suited for these applications, providing stable performance in control systems, motor drives, and monitoring equipment. The wide operating range and high - quality construction ensure that the components can operate continuously in industrial settings without failure.

## Quality Assurance

The SMD125 series undergoes rigorous quality control measures throughout the manufacturing process. From the selection of raw materials to the final testing of the finished components, every step

Images for reference

SMD Series

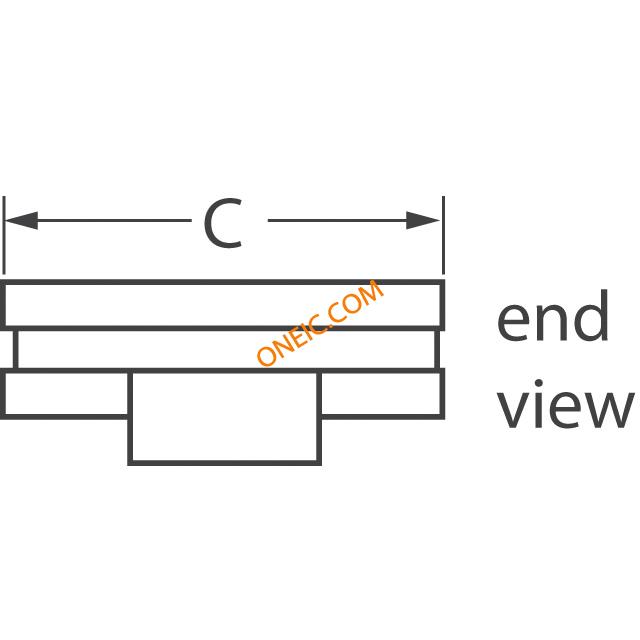

SMDF Series End

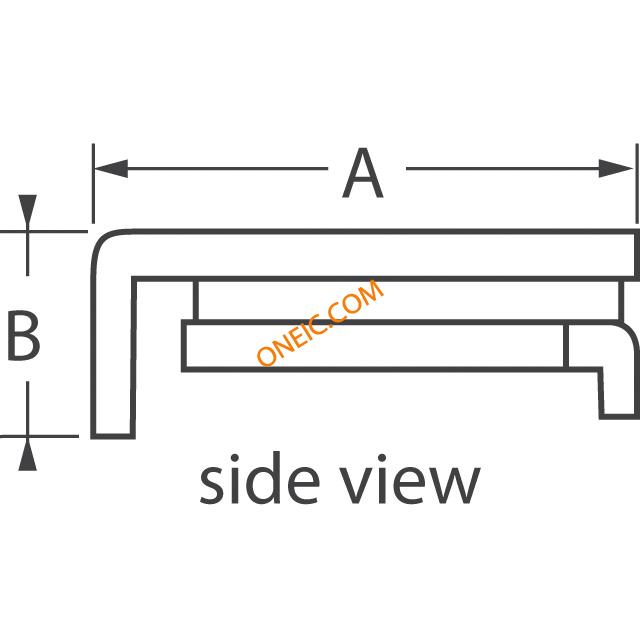

SMDF Series Side