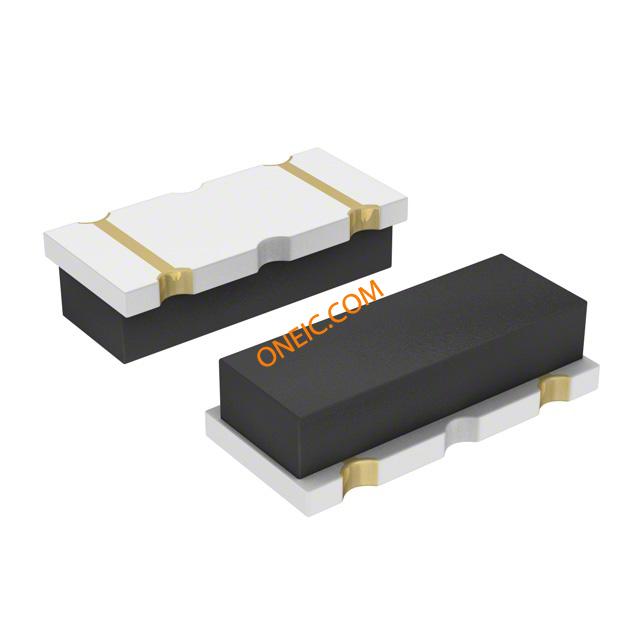

PBRC-4.19

Compact surface mount ceramic resonators for precise frequency applications

Manufacturer: ['avx', 'kyocera']

series introduction

# Unveiling the PBRC - 4.19 Product Series: A Technological Marvel

## Introduction

In the fast - evolving landscape of modern technology, the PBRC - 4.19 product series emerges as a game - changer. PBRC, which stands for Precision - Based Robotic Control, represents a culmination of cutting - edge engineering and innovative design. The 4.19 iteration of this series takes the already impressive capabilities of its predecessors to new heights, offering a comprehensive solution for a wide range of industrial and commercial applications.

## Key Features

### 1. Precision Control

At the heart of the PBRC - 4.19 series is its unparalleled precision control system. Utilizing state - of the - art sensors and advanced algorithms, these devices can execute tasks with an extremely high degree of accuracy. Whether it's positioning a robotic arm within micrometers or controlling the flow of a liquid in a chemical process, the PBRC - 4.19 ensures that every operation is carried out precisely as intended. This precision not only improves the quality of the end product but also reduces waste and increases overall efficiency.

### 2. High - Speed Performance

The PBRC - 4.19 series is engineered for speed. With powerful processors and optimized software, these systems can handle complex tasks at remarkable speeds. In manufacturing environments, this means faster production cycles and increased throughput. For example, in an assembly line, the PBRC - 4.19 can quickly pick and place components, reducing the time required to complete each unit and ultimately boosting productivity.

### 3. Flexibility and Adaptability

One of the standout features of the PBRC - 4.19 series is its flexibility. These devices are designed to be easily integrated into existing systems, whether they are part of a large - scale industrial plant or a small - scale research laboratory. They support a wide range of input and output interfaces, allowing for seamless communication with other equipment. Additionally, the software can be customized to meet the specific needs of different applications, enabling users to adapt the system to their unique requirements.

### 4. Robustness and Reliability

Built to withstand the rigors of industrial environments, the PBRC - 4.19 series is highly robust and reliable. The hardware is constructed using high - quality materials that can resist dust, moisture, and vibrations. Moreover, the system is equipped with self - diagnostic and fault - tolerance features. In the event of a minor issue, the system can automatically detect and correct the problem, minimizing downtime and ensuring continuous operation.

### 5. User - Friendly Interface

Despite its advanced technology, the PBRC - 4.19 series features a user - friendly interface. The intuitive graphical user interface (GUI) allows operators to easily configure, monitor, and control the system. Even those with limited technical knowledge can quickly learn how to use the system effectively. The interface also provides real - time feedback and analytics, enabling users to make informed decisions and optimize the performance of the system.

## Applications

### 1. Manufacturing

In the manufacturing industry, the PBRC - 4.19 series plays a crucial role in automating production processes. It can be used for tasks such as welding, painting, and assembly. The precision and speed of the system ensure high - quality products and efficient production lines. For example, in the automotive industry, the PBRC - 4.19 can be used to precisely weld car body parts, improving the structural integrity of the vehicles.

### 2. Logistics and Warehousing

In logistics and warehousing, the PBRC - 4.19 series can be used to control robotic forklifts, automated guided vehicles (AGVs), and sorting systems. The high - speed performance and precision control of the system enable

Images for reference

PBRC-A Series

PBRC-B Series

Image Preview