HCTL-1100

General-purpose low-power motor and motion control ICs

Manufacturer: ['broadcom', 'avago']

series introduction

# HCTL - 1100 Product Series Introduction

## 1. Overview

The HCTL - 1100 product series is a remarkable set of integrated circuits designed to meet the demanding requirements of high - precision motion control and position sensing applications. These devices offer a comprehensive solution for accurately measuring and processing encoder signals, making them an ideal choice for a wide range of industrial, automation, and robotics systems.

## 2. Key Features

### 2.1 High - Resolution Encoder Interface

- The HCTL - 1100 series is capable of interfacing with various types of encoders, including incremental and absolute encoders. It can handle high - resolution encoder signals, enabling precise position measurement. For incremental encoders, it can accurately count the pulses generated by the encoder, with a high - speed counting mechanism that can keep up with rapid shaft rotations.

- It supports different encoder signal types such as quadrature signals (A, B, and index Z). The quadrature decoding feature allows for accurate determination of the direction of rotation, in addition to the position count.

### 2.2 Programmable Resolution

- One of the standout features of the HCTL - 1100 is its programmable resolution. Users can adjust the resolution of the position measurement according to their specific application needs. This flexibility is crucial in applications where different levels of precision are required, such as in fine - tuning the movement of a robotic arm or the positioning of a machine tool.

- The programmable resolution can be set through simple programming interfaces, providing an easy - to - use solution for system designers.

### 2.3 Low - Power Consumption

- In today's energy - conscious world, the HCTL - 1100 series is designed with low - power consumption in mind. This makes it suitable for battery - powered applications or systems where power efficiency is a critical factor. The low - power operation not only reduces energy costs but also helps in minimizing heat generation, which can improve the overall reliability and lifespan of the device.

### 2.4 Digital Filtering

- To ensure accurate and reliable position measurement, the HCTL - 1100 incorporates digital filtering techniques. These filters can effectively remove noise and interference from the encoder signals, especially in noisy industrial environments. By eliminating false counts and glitches, the digital filtering enhances the accuracy of the position data, leading to more precise motion control.

### 2.5 Serial and Parallel Interfaces

- The HCTL - 1100 series offers both serial and parallel interfaces for easy communication with microcontrollers, processors, or other control devices. The serial interface, such as SPI (Serial Peripheral Interface), is useful for applications where a simple and space - efficient communication method is required. It allows for easy integration into existing systems with minimal wiring.

- The parallel interface, on the other hand, provides high - speed data transfer, enabling rapid access to the position data. This is beneficial in applications where real - time position information is crucial, such as in high - speed motion control systems.

## 3. Applications

### 3.1 Industrial Automation

- In industrial automation, the HCTL - 1100 is used for precise positioning of conveyor belts, robotic arms, and automated guided vehicles (AGVs). It ensures that these machines can move to the exact positions required for tasks such as pick - and - place operations, assembly, and material handling.

- For example, in a manufacturing plant, a robotic arm equipped with an encoder and an HCTL - 1100 can accurately pick up components from a conveyor belt and place them in the correct position for assembly, improving the efficiency and quality of the manufacturing process.

### 3.2 Machine Tools

- Machine tools, such as CNC (Computer Numerical Control) mills and lathes, require high - precision position control.

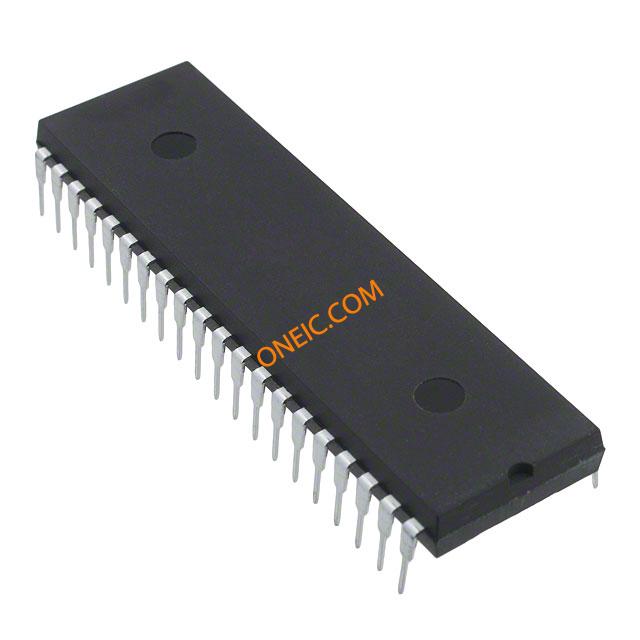

Images for reference

40-DIP

44-LCC (J-Lead)

44-PLCC