D38999/20FJ35BC

Military-grade circular connectors with 128 positions for wall mounting

Manufacturer: ['tyco', 'glenair', 'deutsch', 'amphenol', 'souriau-connection']

series introduction

# Introduction to the D38999/20FJ35BC Product Series

## 1. Overview

The D38999/20FJ35BC product series belongs to the high - performance circular connector family. These connectors are designed to meet the demanding requirements of various industries, especially in harsh environments where reliability, durability, and high - speed data transmission are crucial. They are widely used in aerospace, military, industrial automation, and other fields where the integrity of electrical connections is of utmost importance.

## 2. Design and Construction

### 2.1 Shell Design

- **Material**: The connector shell is typically made of high - strength aluminum alloy. This material offers excellent mechanical properties, including high tensile strength and good corrosion resistance. The aluminum alloy is also lightweight, which is a significant advantage in applications such as aerospace, where weight reduction is a key design consideration.

- **Finish**: The shell is often treated with a special plating, such as cadmium or nickel. Cadmium plating provides excellent corrosion protection, especially in marine and high - humidity environments. Nickel plating, on the other hand, offers good wear resistance and is suitable for applications where the connector may be subject to frequent mating and unmating cycles.

- **Sealing**: The D38999/20FJ35BC series features a hermetic or environmental seal design. The seal is made of high - quality elastomeric materials, such as silicone rubber. This seal prevents the ingress of dust, water, and other contaminants, ensuring the long - term reliability of the electrical connections.

### 2.2 Contact Design

- **Contact Material**: The contacts are made of high - conductivity copper alloy, such as beryllium copper. This material offers low electrical resistance, which minimizes power loss and heat generation during operation. Beryllium copper also has good mechanical properties, including high elasticity and fatigue resistance, ensuring reliable contact over a large number of mating cycles.

- **Contact Configuration**: The series offers a variety of contact configurations, including different pin counts and arrangements. The D38999/20FJ35BC has a specific pin - out that is optimized for high - speed data transmission and power distribution. The contacts are precisely machined to ensure accurate alignment and reliable electrical connection.

- **Contact Protection**: To prevent contact damage during mating and unmating, the connectors are equipped with a contact protection system. This may include features such as contact guides and shields, which help to align the contacts correctly and prevent them from being bent or damaged.

## 3. Electrical Performance

### 3.1 Current Rating

The D38999/20FJ35BC connectors are designed to handle a wide range of current loads. Depending on the specific contact size and configuration, the current rating can range from a few amperes to several tens of amperes. This makes them suitable for both low - power signal transmission and high - power applications, such as power distribution in industrial equipment.

### 3.2 Voltage Rating

The connectors have a high voltage rating, typically in the range of several hundred volts. This allows them to be used in applications where high - voltage electrical signals need to be transmitted, such as in some aerospace and military systems.

### 3.3 Signal Transmission

For high - speed data transmission, the D38999/20FJ35BC series offers excellent signal integrity. The connectors are designed to minimize signal attenuation, crosstalk, and electromagnetic interference (EMI). They can support data rates of up to several gigabits per second, making them suitable for applications such as high - speed data communication in avionics and military radar systems.

## 4. Environmental Performance

### 4.1 Temperature Range

The D38999/20FJ3

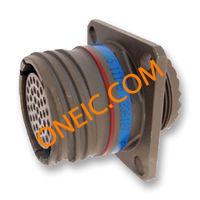

Images for reference

Image Preview

Image Preview

Image Preview