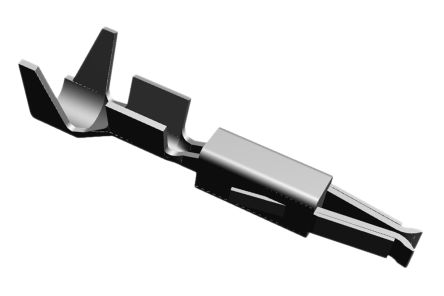

962876-1

Automotive crimp socket contacts for Micro-Timer II connectors

Manufacturer: tyco

series introduction

# Introduction to the 962876 - 1 Product Series

## Overview

The 962876 - 1 product series represents a cutting - edge line of products engineered to meet the diverse and demanding needs of modern industries. This series combines advanced technology, high - quality materials, and meticulous design to deliver outstanding performance, reliability, and functionality. Whether you are in the manufacturing, engineering, or service sectors, the 962876 - 1 series offers solutions that can enhance your operations and drive efficiency.

## Key Features

### 1. Advanced Technology Integration

- **Precision Engineering**: The products in the 962876 - 1 series are built using state - of - the - art precision engineering techniques. This ensures that each component is manufactured to exact specifications, resulting in products with high accuracy and repeatability. For example, in applications where precise measurements or movements are required, such as in automated manufacturing processes, the precision of these products can significantly improve the quality of the final output.

- **Smart Functionality**: Many of the products in this series are equipped with smart features. They can be integrated with modern control systems, allowing for remote monitoring, adjustment, and automation. This smart functionality enables users to optimize their processes, reduce downtime, and make data - driven decisions. For instance, sensors in the series can collect real - time data on various parameters such as temperature, pressure, or vibration, and transmit this information to a central control unit for analysis.

### 2. High - Quality Materials

- **Durable Construction**: The 962876 - 1 series is constructed using high - grade materials that are selected for their durability and resistance to wear and tear. Metals used in the manufacturing process are often heat - treated and coated to enhance their strength and corrosion resistance. This makes the products suitable for use in harsh environments, such as industrial plants, outdoor installations, or marine applications.

- **Chemical Resistance**: In addition to mechanical durability, the materials used in the series also offer excellent chemical resistance. This means that the products can withstand exposure to a wide range of chemicals, solvents, and corrosive substances without degradation. This is particularly important in industries such as chemical processing, where equipment needs to be able to handle aggressive chemicals safely.

### 3. Versatile Design

- **Multiple Configurations**: The 962876 - 1 series comes in a variety of configurations to meet different application requirements. Whether you need a compact design for space - constrained environments or a larger, more powerful version for heavy - duty applications, there is a product in the series that can fit your needs. For example, the series may include different sizes of pumps, motors, or valves, each with its own set of performance characteristics.

- **Easy Integration**: The products are designed for easy integration into existing systems. They are compatible with standard industry interfaces and protocols, making it simple to incorporate them into your current setup. This reduces the need for extensive modifications or customizations, saving time and money during the installation process.

## Applications

### 1. Manufacturing

- **Automated Production Lines**: In automated manufacturing, the 962876 - 1 series can be used for tasks such as material handling, assembly, and quality control. For example, precision motors in the series can be used to drive conveyor belts, ensuring smooth and accurate movement of products along the production line. Sensors can be used to detect defects or measure product dimensions, enabling real - time quality control.

- **Machine Tools**: The high - precision components in the series are well - suited for use in machine tools. They can provide accurate positioning and movement control, improving the machining accuracy and surface finish of the workpieces. This is crucial in industries such as aerospace and automotive manufacturing, where tight tolerances are required.

###

Images for reference

Image Preview

Image Preview

Image Preview